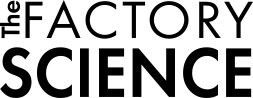

Industry 4.0 International Megatrends

December 23, 2021

Industry 4.0 predicted 55 years back -Jetsons show

January 4, 2022The International Society of Automation ISA-95

The ISA-95 term is familiar to maximum industry or technical specialists running the business with IIoT. International Society of Automation is a global standard for growing an automatic interface among business enterprise systems/programs and business control systems. This standard was framed to be carried out in all industries and in all forms of industrial process.

This standard is bridging the gap between IoT computing layers and ISA-95 automation levels, as well as the developing constructions of Industry 4.0. There are still challenges that exist in the IIoT of integrating the OT and IT, where the IT give priority to data, governing the data to make sure that the industries users are satisfied. On other hand, the OT focuses on the safety of assets, humans, and the production process. Moreover, these challenges are making the OT-IT convergence process complex.

ISA-95 for IIoT

Industry 4.0 or IIoT is reexploring the path that industries communicate about industrial manufacturing incorporation. Learn more on the Industry 4.0 megatrends. Moreover, the IIoT is moving the industries towards the smart connected systems or smart industries. Learn more on Industry 3.0 vs Industry 4.0.

In a manufacturing context, the ISA 95 data model provides six different processes of automation where data is generated, processed, or transferred. This data format is based on UML that is already exists for data exchange between MOM (Manufacturing operations management) and ERP systems. It specifies the logic and operational strategies for how industrial control systems, communicate with enterprise resource applications. Communication between diverse stakeholders in a manufacturing process, such as vendors, production lines, and distribution networks, is made feasible by the ISA 95 standards.

ISA-95 comprises six sections, each one develops on the previous one:

- The first section defines hierarchical patterns, operational data processing models, physical models, and production activity, models.

- The second section defines the characteristic and structure tables of each object in the first section

- The third section expands on the definition of the components by specifying the activities or interactions that occur between them. It specifies the manufacturing operations management (MOM) that allows the enterprise and control systems to work together.

- The fourth section includes the processing models, data flow between MOM classes, and activities.

- The fifth Section includes the transferring data, data collection, retrieval, storage that take place in the industries.

- The sixth section is a messaging system approach for connecting business and industrial apps.

Reference- IoT Agenda.com

Picture Reference – blogInresearch.com

For IIoT architects, ISA-95 is a great place to start, and industry people should consider how to enhance it with proper infrastructure and cybersecurity.

The fact of today’s MOM implementations is really unique. Most MOM structures use a database-centric structure that lets in the distinct applications to share information via the database. This is simple to put into work.

However, the IIoT offers the opportunity to bring together smart connected devices and assets and the data associated with them in an unlimited number of ways.

Now is the time to take the industries to step into IIoT. The IIoT, allows you to connect smart connected devices and assets, as well as the data associated with them, in an infinite variety of ways.

And a better starting point is ISA-95: its objects, IO, and behaviors, and also control information about devices that you expect to be smart connected devices in your future IIoT journey.

Check your Industry 4.0 competency level with following free self-assessment tool:

So, to upskill yourself, or your workforce or to start a career in Industry 4.0, The Factory Science Diploma in Industrial Digitization Program helps for the successful transformation.

For regular updates:

Join us @ WhatsApp

Join us @ Quora

Join us @ LinkedIn

Join us @ Facebook

Please share this article to accelerate awareness about Industry 4.0.