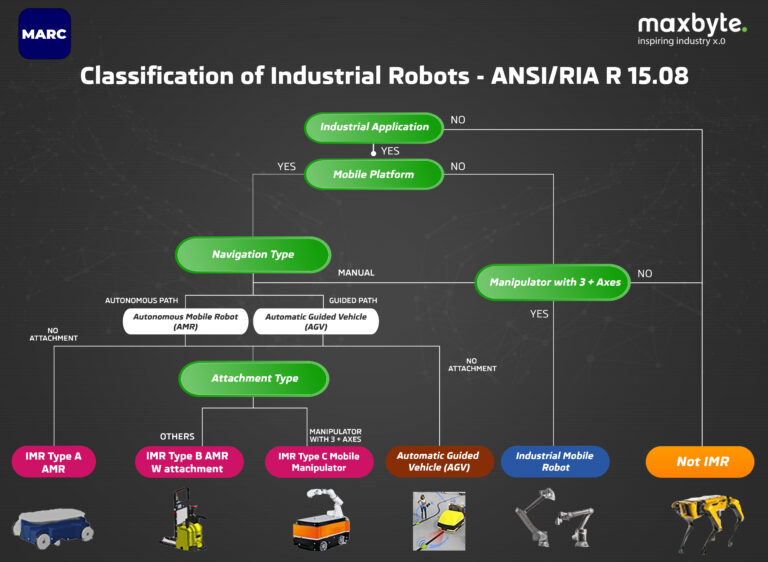

Classifications of the industrial robots based on the ANSI/RIA R15.08

January 10, 2022

Virtual Reality (VR) Based Training for Operation Safety

January 12, 2022The Internet of things is taking the world to a new path, as the global Internet of Things (IoT) market is projected to grow from $381.30 billion in 2021 to $1,854.76 billion in 2028 at a CAGR of 25.4% in the forecast period said by fortune business insights. The OT focuses on the physical processes and other distinct tasks (controls machines/assets) in the manufacturing floor, Where the IT focuses on the data and data storage systems. The IT and OT are completely seen as in a different perspective but now it’s completely changed. The IIoT paved a way to converge these two different sectors into a combined solution and help the industries to perform effectively and efficiently.

Let’s see in detail about OT Versus IT and its convergence.

What is operational technology?

Operational Technology is different from IT (Information technology) and it comprises hardware and software to do some tasks like monitoring, controlling the physical devices and other processes (controlling the temperature, observing the machines/assets performance, etc…) of the industries. ICS (Industrial control systems) is the most well-known type of OT to perform the tasks related to OT and the SCADA (Supervisory Control and Data Acquisition) are used for collecting real-time data and running the industrial equipment.

What is Information Technology?

Information technology is in contrast to operational technology, the IT is merging the different machines with a better machine to machine interaction in case of transforming the data. IT performs the more automated and computational process (collecting, managing, retrieving, and manipulating data) or performing all data processes, telecommunications, managing networks, and giving the industries on-time insights as well as standing as the technical support and backbone to the industries.

Converging OT and IT

Converging of OT and IT involves connecting the two different industrial priorities into a single cohesive system. The OT and IT are converged to give an effective solution called IoT.

IIoT is combined to bridge the gap between the connectivity of OT and IT to the industries and it creates multiple industries to use and adapt the IIoT. However, the OT and IT are combined to give smart solutions to the industries, for example, highly automated process for collecting data from sensors, and giving prior instruction about the equipment that goes to cause failure or alerting the workforce in prior about the damaged component that going to fails or stop the machine operations.

This smart solution also gives the workforce the real-time monitored data to edit and update the corrections very quickly. For example, it alerts with an alarm to notify the workforce about the defective part in the system (which cause serious situation) before it goes wrong.

Therefore, the convergence of the OT and IT (IIoT) or the need for the IIoT has increased among all industrial sectors (oil/gas refinery, construction and more) and the industries are willing to adopt in their industries.

Benefits:

- The large volume of data for visibility into condition and status

- Enhanced security and better performance

- Improving Customer service

- Respond faster to real-time conditions

- Predictive maintenance, ultimate decision making, and higher OEE.

- Better management of the business

- Helps introduce the quality product

- Downtime is reduced, and maintenance costs are reduced.

- Simplify, Optimize, and Enhance Business

- Data Analytics provides better insights.

- Prioritize work to reduce the risk of out stages

However, the industries are adopting the IIoT solutions but there is a need for their workforce to upskill themselves with Industry 4.0 technologies like IoT, AI, Autonomous mobile robots, AR/VR, Machine learning etc…

Check your Industry 4.0 competency level with following free self-assessment tool:

So, to upskill yourself, or your workforce or to start a career in Industry 4.0, The Factory Science Diploma in Industrial Digitization Program helps for the successful transformation.

For regular updates:

Join us @ WhatsApp

Join us @ Quora

Join us @ LinkedIn

Join us @ Facebook

Please share this article to accelerate awareness about Industry 4.0.