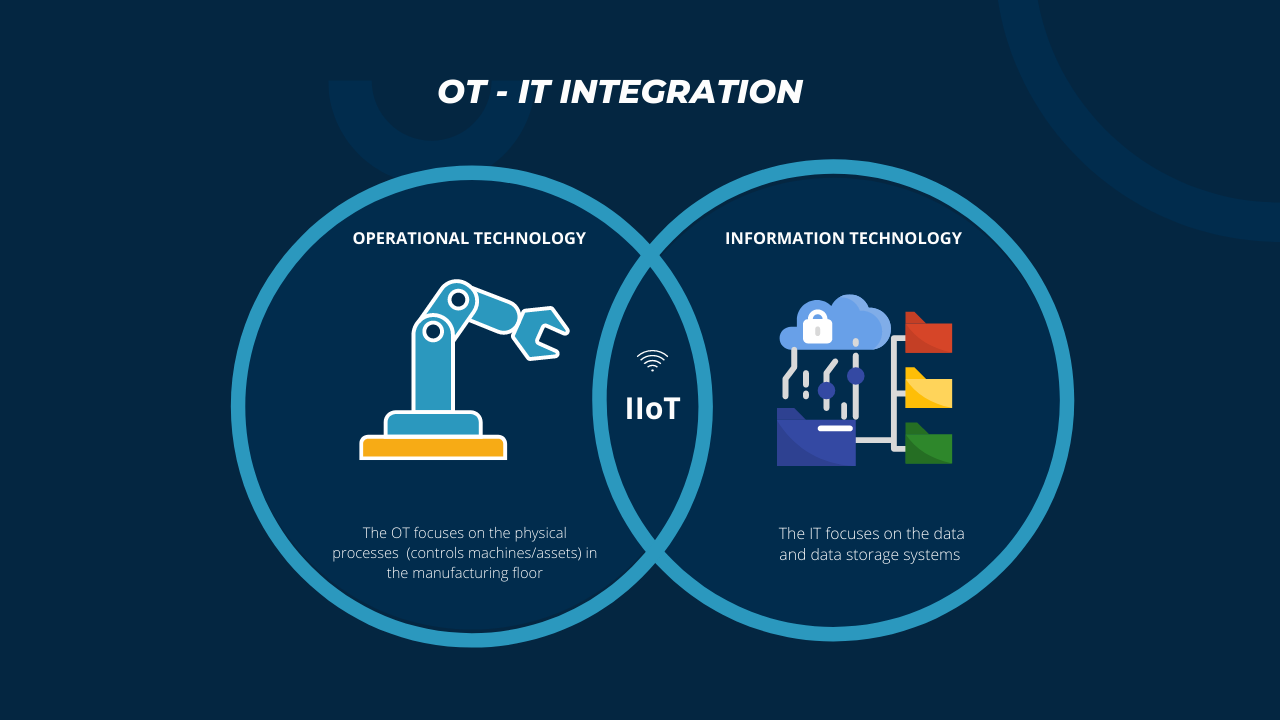

OT-IT Integration

January 11, 2022

AR for Remote Expert Guidance and Support

January 17, 2022

Virtual reality is growing rapidly and the adoption rate of VR for industries are also increasing due to its immersive benefits and interactive nature. As the introduction of new technologies and the shortage of skilled labour’s (who don’t have experience) with new technologies are also some of the reasons for adopting Virtual reality based training. Moreover, for a long time, industries are relying on manual, in-person training, lectures for conducting safety training but Virtual reality training is different from the other training ways, where people can touch, interact, and experience the real-world environment. In the case of virtual based safety training for maintenance features, it allows the workforce to get a practical working knowledge. For example, preventing equipment accidents or safety accidents before it causes injury or damage.

Why VR based safety training?

As there are many challenges are faced by the industries like not being cost-effective, no resources availability, lack of interactivity with the real environment, less knowledge retention and taking more time. Therefore, the VR based training gives a solution where it allows employees or the workforce to feel the real working situations and shows the problems they need to encounter and actions they need to take and also allow them to experience outcomes of their actions.

However, this brings confidence among the workforce and they can interactively work in a safe world. Multiple industries are adopting Virtual reality for the reduction in workplace injuries and its immersive benefits.

VR based safety training system for industries

Virtual reality in safety training prepares the workforce to experience risky situations and provides them with practical experience and as well as feel safe. In VR safety training the industries can create a different industrial situation to train employees with different scenarios and it’s more beneficial for the high-risk industries. Virtual reality safety training system provides a faster, cost-effective, and more immersive solution. VR based safety training system can be helpful to gain memorable, interactive learning experience to practice hands-on skills and reinforce knowledge in several virtual environments.

VR experience-based safety training with different user safety training screens

– PPE Kit

– Material Handling

– Hazardous area

– Electrical & Mechanical systems

– Critical Operation & Assembly instructions

– Interactive training session by providing better VR interactive tools

– Safety, O & M training examination with scorecard through VR experience for new joiner & any factory visitor.

The VR based safety training system for maintenance features are designed for interactive, realistic simulation, safe virtual environment, more knowledge retention and VR is adherence with ISO 45001 /OHSAS standards.

Benefits

- It improves the workforce jobs performance

- Assist you in lowering the cost of training workforces of all sizes.

- Allow you to provide standardized training to all employees

- Virtual reality gives more effective training

- Preparing workforce to handle emergencies

- Assisting employees in the development of technical skills

Therefore, the industries can adopt the VR based safety training system to train and update their workforce to upskill themselves and work effectively, safely in the manufacturing floor.

Check your Industry 4.0 competency level with following free self-assessment tool:

So, to upskill yourself, or your workforce or to start a career in Industry 4.0, The Factory Science Diploma in Industrial Digitization Program helps for the successful transformation.

For regular updates:

Join us @ WhatsApp

Join us @ Quora

Join us @ LinkedIn

Join us @ Facebook

Please share this article to accelerate awareness about Industry 4.0