Industry 4.0 predicted 55 years back -Jetsons show

January 4, 2022

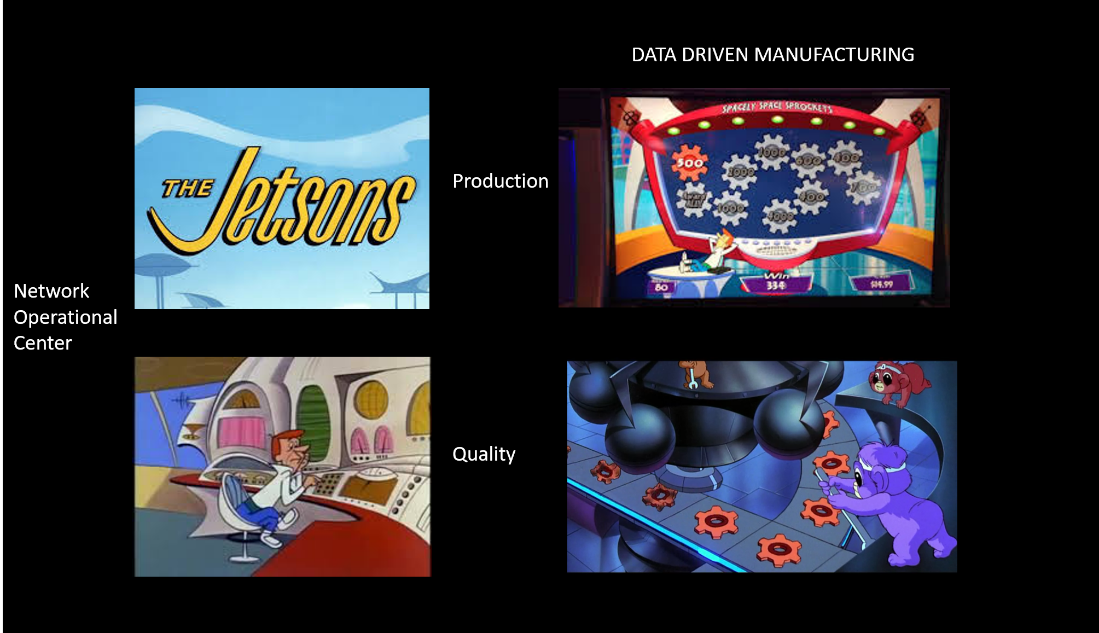

Classifications of the industrial robots based on the ANSI/RIA R15.08

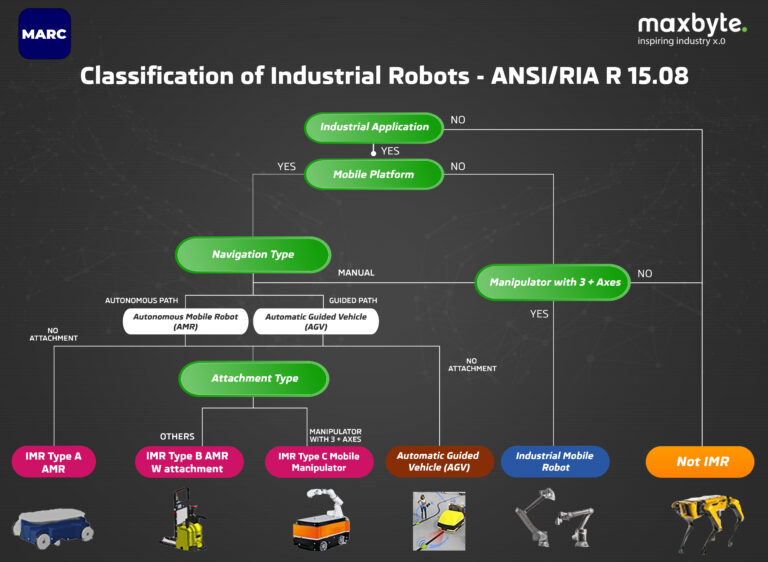

January 10, 2022ISA-95 is an International Society of Automation

ISA 95 is a global standard framed for the integration of enterprise and control systems and for the industries involved in the manufacturing, automation and more. This international standard was not just framed by a single industry, multiple companies are part of framing this standard. Learn more on aligning iiot and ISA 95

This standard has multiple industrial best practices, in the form of terminologies and models to use in their industries with integration of ISA –95. Moreover, the ISA-95 standard will help to reduce the cost, reduce risks and enhance the communication between the process that occur in the industries.

ISA 95 standard has different sets of standards for different processes in the industries and enterprises.

ISA-95 Part 1 Models and terminology

Standard 1 defines the integration of set of models and terminologies that can be used as the industry best practices for the manufacturing operations, control systems and business systems carried out in the enterprise.

ISA-95 Part 2 Object model attributes

Part 2 is the standard model for transferring the data like (batch control, continuous control, discrete control (control systems), table of attributes, using the UML model mentioned in the part I model.

ISA-95 Part 3 Activity Models of Manufacturing Operations Management

The ISA-95 part 3 describes the processes that occur in the production management or manufacturing operations (dispatching production, detailed production scheduling, reliability, assurance) where distinct information’s are transferred.

An actual situation in your industry can be known with this model.

ISA-95 Part 4 Object models and attributes for Manufacturing Operations Management

The ISA 95 determines the activities/ data that are to be transferred between the distinct MES activities, (that are determined in part 3), control systems, MoM activities in the enterprise.

Moreover, this part is in developing stage by the SP-95 committee.

ISA-95 Part 5 Business to manufacturing transactions

The ISA-95 part 5 defines the data that is transferred between the business systems/ business management process and manufacturing operations related to the level 3, and 4.

The data that is transferred is planned to collect, retrieve, exchange and store the data/information. These transactions are processed to form a better enterprise control system integration.

This part 5 also defines the models specified with part 1 and 2.

ISA-95 Part 6 Message servicing model

This model defines the messaging services, the data or information’s that are transferred between the business, manufacturing operations performing applications associated with the 3, 4 levels of the ISA 95 systems.

Models Reference-ISA 95.com

Image Reference-researchgate.net

The purpose of the ISA-95 is to create a system based on the Purdue Reference Model for CIM (hierarchical form) as released by ISA and to specify the interface between control functions and other enterprise functions.

The goal of this standard is to reduce the risk, expense, and errors that come with different process that carried out in the industries.

Check your Industry 4.0 competency level with following free self-assessment tool:

So, to upskill yourself, or your workforce or to start a career in Industry 4.0, The Factory Science Diploma in Industrial Digitization Program helps for the successful transformation.

For regular updates:

Join us @ WhatsApp

Join us @ Quora

Join us @ LinkedIn

Join us @ Facebook

Please share this article to accelerate awareness about Industry 4.0.